The design of the Lean Six Sigma programs allows participants to acquire skills that can improve business processes and outputs while introducing them quantitative tools for quality. Lean Six Sigma is an appropriate approach for businesses seeking to enhance their…

The design of the Lean Six Sigma programs allows participants to acquire skills that can improve business processes and outputs while introducing them quantitative tools for quality. Lean Six Sigma is an appropriate approach for businesses seeking to enhance their efficiency, adaptability, and responsiveness by improving tangible products, intangible services, and digital offerings.

In the following interview, Dr. Reiner Hutwelker, Lean Six Sigma Master Black Belt and Senior Lecturer at Technical University of Munich (TUM), provides insights on Lean Six Sigma, how it complements other systems, its target groups, certification criteria, teaching goals, and how the training works.

What is Lean Six Sigma?

Dr. Reiner Hutwelker: Lean and Six Sigma are complementary management systems for improving business processes and their outputs. They are neither product nor industry specific and are therefore suitable for optimizing tangible products, intangible services, and digital entities.

Complementary systems: What makes them different and how do they complement each other?

Dr. Reiner Hutwelker: Lean thinking is like a fitness program for companies. It includes methods and principles for harmonizing processes in terms of time, avoiding waste and losses, and increasing efficiency and effectiveness. We do this ourselves every day when we avoid detours and duplication of work, reduce waiting times, are economical with resources and thus optimize our everyday life in small steps. This idea is implemented in lean initiatives. Lean methods, tools and principles are introduced throughout the company for the overarching, coordinated, continuous improvement, to increase the productivity, flexibility and responsiveness.

Six Sigma is more like a medical intervention for a specific issue. Every Six Sigma project starts with a problem. And problems are deviations of process outputs from customer and management requirements. For example, our certificate projects focused on pinholes in drug packaging, on blisters in coatings, on incorrect amounts in money transfers, on errors in drawings, wrong bundling of software components into custom cloud apps, on inefficient transportation in a mine, on trash in public spaces. The scope of Six Sigma is very broad, but the focus is always the same: it’s about outputs and their deviations in quality, availability, and resource consumption.

Lean – general fitness, Six Sigma – specific treatment – they differ and complement each other.

So the Green Belt certification is about the implementation of a specific project. Which target group do you want to address with this certificate course?

Dr. Reiner Hutwelker: Lean Six Sigma is neither industry nor process or product specific but has its strengths in existing routine processes that are executed at least once a day. Every employee is involved in processes and therefore we address all employees and managers of companies that want to solve an opaque, repetitive problem, maybe to increase customer satisfaction, maybe to reduce costs. If it is foreseeable that the expected benefits from the project will exceed the cost of the project plus course fees, the first decision to certify with us may already have been made.

Companies are the typical target group for Lean Six Sigma. However, you are already targeting students with the course.

Dr. Reiner Hutwelker: Yes, with great pleasure. We offer a predefined project on littering in public spaces. Litter on the street can be defined as a problem and dealt with using Lean Six Sigma. Currently, students from 51 countries are collecting data from their own peer groups as well as field data on littering in their own city. The goal is to understand the causes and reduce the amount of litter in selected spots. Although in many projects the ecological benefit is small, the topic motivates and sensitizes our students – and we combine the useful with the necessary.

The size of the project’s success cannot then be a certification criterion. What are your criteria for certification?

Dr. Reiner Hutwelker: Yes, the extent of success is irrelevant for certification – this applies to individual business projects and to our predefined Sustainability Project. Our criteria are based on the demonstrated method and tool competencies.

We are concerned with the step-by-step acquisition of theory, the transfer and the direct application. Critical are the planning, collection and evaluation of information and data, the interpretation of the results, drawn conclusions and the resulting decisions. We monitor this process – and this is atypical.

It is typical for analog and digital Lean Six Sigma providers that projects are not accompanied and only a final project review takes place. This reflects the thoughts on quality assurance from the last century – at the end, it is checked whether the car runs or not.

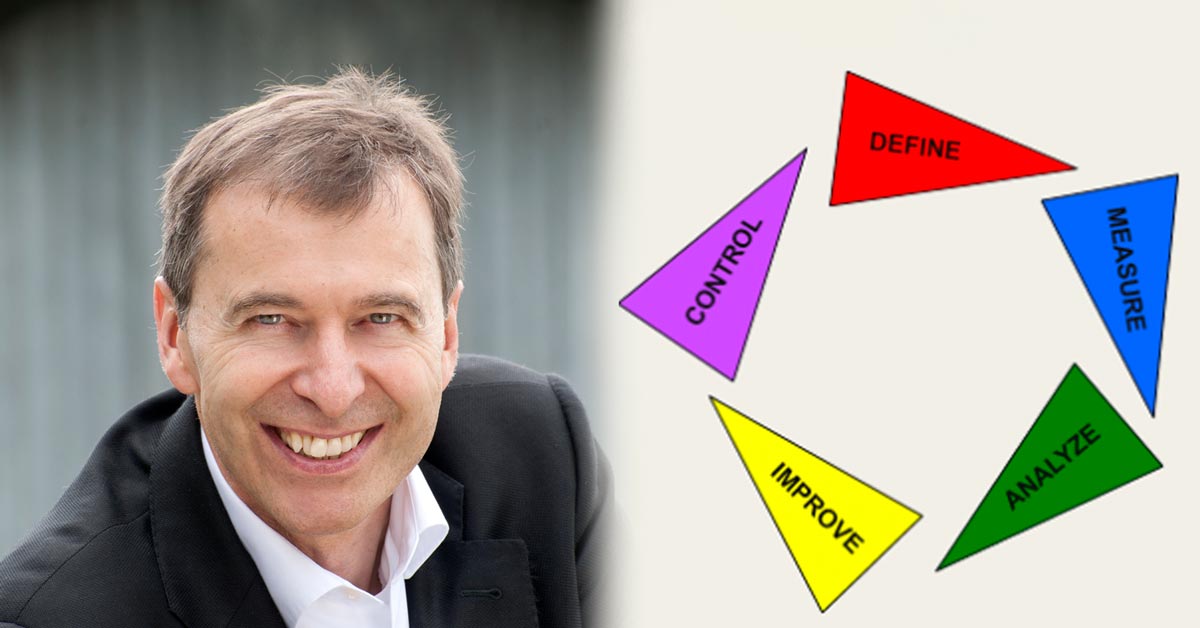

We monitor and manage the acquisition of competencies. Each project proceeds along the 5 DMAIC phases: Define, Measure, Analyze, Improve and Control. The tool chain is linked to these phases and an application complex is completed after each phase. We review and comment on the documentation of each phase in a timely manner. In this way, we control projects methodically. In business projects, the manager can control the content of the project. The successful completion of all phases then leads to certification – together with the results of the knowledge test.

Which teaching goals are to be achieved?

Dr. Reiner Hutwelker: The core of the trained competence is the ability to ask scientific questions, to observe objectively, to formulate hypotheses, to collect and evaluate data, to detect important results, differences and correlations, to interpret them, to draw conclusions, to make decisions in order to finally be able to verify the success.

How does the training work in concrete terms?

Dr. Reiner Hutwelker: We differentiate between individual business projects for employees and our predefined sustainability project for students. Students can enroll directly on the eLearning platform edX.org for our Green Belt certification. Employees of companies and their managers may first express their interest via our TUM Lean Six Sigma Green Belt homepage. Because before enrolling, we first need to clarify the prerequisites: Is the project fundamentally suitable, how complex is it, what potential does it have, does management support its implementation?

The course material is identical for all participants. Our videos and the eBook for the course demonstrate a Lean Six Sigma project along the DMAIC phases step by step in a familiar scenario. Each of these steps should be directly applied by the learner to their own project.

Support is provided by a software guide with tools, our Minitab statistics licenses for data analysis, and a template for documenting the project.

In addition to this digital guidance, we offer personal guidance. This includes weekly zoom lectures where topics are explored in depth, questions are answered, and outstanding sustainability projects are presented. Feel free to drop by, the event is open to the public. Individual business projects are additionally supported by personal, project-accompanying coaching to secure goals, monitor tool application and optimize project progress.

The course has already won several international awards, and is currently on the shortlist for the edX Prize 2023. What makes this course different?

Dr. Reiner Hutwelker: We put a lot of effort into the scientific framework, which we adapted to Six Sigma. The reliability and validity of the approach were important to us, so that learners can move forward sure-footed, effectively, and efficiently.

We also view the project itself as a (education-)process with the competency and the certificate as the outcome. Therefore, we ourselves apply Lean Six Sigma to the development and operation of our course to optimize the media match between our videos, our tools, and templates.

Overall, the digital material enables project implementation, but does not guarantee it. That’s why we additionally offer personal guidance, for the complete course, groups and individually. Here we are interested in the optimal balance between digital and personal support.

We are flexible. You can join anytime, 24/7/365. You could also work on a larger project with a colleague. We have learners working on the same problem in different locations of their company.

Our learners appreciate both sides of our blended course – the scientifically oriented, transparent approach in our digital material and the personal support, in the project itself and by our program management at the Institute for LifeLong Learning. We know this from the testimonials at classcentral. In 2022, we were once again ranked number 1 there. Editors and learners say, that we make a difference.

Interested?

Are you too looking to continue your lifelong learning goals and develop your skills on business productivity? Check our Lean Six Sigma Yellow Belt Certification or an overview of the quality and productivity improvement processes and Lean Six Sigma Green Belt Certification for combining the theory impact with individually coached projects.